March 2024 – WEEK 1 TOOLBOX TALKS TOPIC: Who Is Responsible For Safety?

Safety is everyone’s responsibility! As an employee, you should:

- Learn to work safely and take all rules seriously and recognize hazards and avoid them.

- Report all accidents, injuries and illness to your supervisor immediately.

- Inspect tools before use to avoid injury.

- Wear all assigned personal protective equipment.

On the other hand, it is management’s responsibility to:

- Provide a safe and healthy workplace and provide personal protective equipment.

- Train employees in safe procedures and in how to identify hazards.

Everyone must be aware of potential hazards on the job:

- Poor housekeeping results in slips, trips and falls.

- Poor material handling may cause back problems or other injuries.

- Tools and equipment can cause injuries if guards or protective devices are disengaged.

Always use the protections that are provided on the job:

- Machine Guards keep body parts from contacting moving equipment.

- Personal protective equipment shields your body from hazards on the job.

Safety benefits everyone. With fewer injuries, a business can be more productive and profitable. By incorporating safety rules, employees avoid injury as well as illness from exposure to hazardous substances.

March 2024 – WEEK 2 TOOLBOX TALKS TOPIC: LUCKY ESCAPES

Close call incidents do not often result in injuries.

However, ignoring a close call means you could be paving the way for a serious injury to happen. You must report all close calls so they can be investigated and the hazard removed before someone does get hurt. For every reported first aid or minor injury, there are on average hundreds of close calls incidents that have gone unreported.

Close calls (also known as near misses) are situations in which a worker has a narrow escape from getting hurt. The worker probably feels lucky about getting away uninjured. If we pay attention, these incidents can be lucky in another way: They provide a preview of an injury that could happen, so measures can be taken now to prevent it.

Here’s an example: A carpenter’s assistant picks up a power drill and gets a slight electric shock. He quickly drops the tool, suffering no injury. At this point, he has an important choice to make. If he just forgets the incident, the next person to pick up the tool may have damp hands or may be standing in a puddle of water. That person is bound to get a severe shock. However, if the incident is reported, the tool will be removed from service, checked over and either repaired by qualified personnel or discarded. There will also be a chance to find out why this tool became defective. Was it poorly designed or manufactured? Has the insulation been allowed to get wet or is the cord frayed? How can problems be avoided in the future – perhaps by buying better tools, taking good care of them and inspecting them regularly?

MARCH 2024 – WEEK 3 TOOLBOX TALKS TOPIC: LIFTING

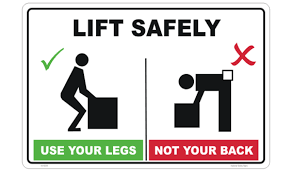

Do you realize you may be risking serious injury many times a day and not even know it? Well, it’s true if you don’t lift correctly. Improper lifting may cause back injuries that can take months and even years to heal. Sometimes they are permanent and disabling. A little know how, however, can enable you to lift correctly.

PREPARING TO LIFT

Give the load the once-over. If it looks too heavy, don’t be afraid to ask for help. Be sure you’re wearing safety shoes. There is always the chance of dropping something on your toes. If the object has rough or sharp edges, wear a good, tough pair of work gloves. They’ll give you a good grip and protect your hands.

MAKING THE LIFT

Crouch down with the load between your legs and get a good grip on the object. As you rise, lift with your legs, keeping your back vertical and the load as close to your body as possible. If you have to place the load to your left or to your right, don’t twist your body. Move your feet instead. When you have to lower a load, simply reverse the knees bent, back vertical procedure.

LET’S REVIEW

Let’s quickly review what we said about lifting:

1. Don’t lift more than you can handle. Ask for help with heavy loads.

2. Wear safety shoes.

3. If the object is rough or sharp, wear gloves.

4. Lift with your legs and not your back.

5. Keep the load close to your body.

6. Don’t twist your body when placing a load to one side or the other. Move your feet instead.

MARCH 2024 – WEEK 4: Complacency/Carelessness

Webster’s Dictionary defines complacency as:

self-satisfaction especially when accompanied by unawareness of actual dangers or deficiencies

Complacency is perhaps one of the biggest problems we face in completing our day to day tasks. We are “used” to things being a certain way each time and unless the obvious comes right out and hits us . . . we can be oblivious to it all. This is state of mind can affect many things such as productivity, quality and safety.

Here is an example:

According to a research at Cmabrigde Uinervtisy, it doesn’t matter in what order the letters in a word are, the olny iprmoetnt tihng is taht the frist and lsat ltteer be at the rghit pclae. The rset can be a toatl mses and you can sitll raed it wouthit porbelm. Tihs is bcuseae the huamn mnid deos not raed ervey lteter by istlef, but the wrod as a wlohe.

You probably didn’t have much trouble reading that paragraph. It probably took you back at first, but then you were able to zip right through the text and understand the content. This is an example of how complacency works with our mind. We get used to words starting with certain letters and being a certain length and we skip right over it “thinking” we know what the word is.

In reading paragraphs it’s not a big deal . . . however when it comes to safety, complacency can be a literal “killer” on the job. There is much danger in going into “autopilot” when working on the job. All too often we don’t realize how complacent we are until we have a near miss or close call.