Week 1- Back Injury Prevention

A back injury on the job is a very common occurrence. When there are lifting projects and other tasks at hand, it is almost impossible to prevent it 100% of the time. It has been recorded that over one million workers over a year’s time span suffer from some type of back injury on the job, making back injury prevention all the more needed. For every 5 incidents that happen in the workplace, one of those is said to be a back injury. Worker’s compensation claims are made up largely of back injury claims each year. But, there are rules and regulations that can be put into action to help protect the safety of everyone.

In the workplace, there are some things that can be put in place to help protect the employees and the company. By doing everything you can to help prevent an injury the better. Guidelines that are set into place should be followed by all employees while working.

1. Preform Stretch and Flex Exercises

The employee may take it upon themselves to stretch before starting and using reasonable judgment when on the job. Use equipment for lifting or ask for assistance when needed. Be sure you know your limits before stretching!!

2. Eliminate Unnecessary Lifting

To avoid back injuries on the job, it is recommended that you eliminate as much manual lifting as you can. The company should make lifting equipment available so the lifting is minimized. Dollies, forklifts, and other similar equipment can be beneficial to protect the employees. Protecting you as the employee, from back injuries in any way possible.

3. Guidelines By Administration

It is ideal to make sure that the employees who are lifting heavy items are fully capable of the job that you have them doing. The administration should make rules clear about weight limits for lifting and when to ask for help. A supervisor should be involved with weight limits over 100 lbs., to help ensure optimum safety of the employees.

4. Engineering Controls

The setup of the warehouse or area that the employees are working in should be set up to benefit them and make their job as safe as possible. All shelving and storage areas should be at a reasonable level to lessen the height at which they are lifting objects. The necessary equipment to lift and move boxes should be made available when possible.

Week 2- Slips/Trip and Falls

Each year too many construction workers are injured by slips and falls.

Slipping on the floor is bad enough, but falling from a height can be disastrous.

How can falls be prevented? Keep your eyes open!

When working at heights, proper guard rails must be used and, where necessary, safety belts that are properly tied-off.

Scaffolding must rest on firm footing and should have all the bracing installed. When using multi-level staging, the scaffolding must also be anchored to the structure. First quality cleated planks, completely covering the working level, are a necessity.

Orderliness plays a big part in preventing slips and falls. Debris lying around on floors and working areas is an open invitation to accident. Weather increases hazards, particularly in winter when debris becomes snow covered and cannot be seen. Ice conditions create additional dangers. Sand and/or calcium should be applied to icy areas.

Wet weather causes muddy feet which contribute in turn to slips and falls. Wipe your feet before climbing steps or entering a work area.

When climbing a ladder, hold on with both hands. When walking down stairs use the guardrail.

REMEMBER! Your eyes are your best defense against slips and falls. Watch your step and look where you are going.

Week 3- Working around Cranes

EXPERIENCE CAN BE THE WORST TEACHER

Experience teaches us a lot about working around cranes. But often the lessons are costly. For example: A laborer carrying a bag of cement walked between a crawler crane and a building column. The crane swung round and fatally crushed him between the counterweight and the column. On another job, a workman was leaning on the crane frame, talking with one of his buddies. The load came in contact with a live power line and he was electrocuted. Today, we’ll discuss things we should and should not do when working around this equipment.

STAY OUT FROM UNDER

It’s a smart move on your part to stay out from under suspended hooks and loads. There’s always a chance that during a lift, the load could shift and fall. It may be a slim chance because of the good rigging techniques we use. But once is all it takes to cause a serious injury or a fatality. Also stay clear of swinging loads. That big “I” beam can squash you like a bug if you get in the way.

YOU’RE NOT SAFE WHEN NOT SEEN

Remember, too, that the crane operator may not see you. He’s concentrating on moving his crane into position or swinging his load. Think of the swing area of the crane as “no- man’s land.” And stay out. The crane will have no sympathy if you get in the way. And it won’t come out second best. I’ll guarantee that.

OTHER DANGERS

Have you ever heard of a P.L.P.? It stands for Public Leaning Post. And a lot of people think that’s what the crane is. They’re asking for a shocking experience if the load or boom touches a live wire. So don’t lean on the crane. Stay clear. It’s too bad the workman we talked about earlier didn’t take this advice. He’d still be around today. Of course, with all the overhead work going on, we always should wear our hard hats. Concrete slopped out of a lifted bucket can crack an unprotected skull. I don’t understand why some persons never use the stairs or personnel hoists. They insist on “riding the hook.” And they’re asking for trouble when they do. It’s one of the most dangerous means of transportation around.

USE EXTRA CARE AROUND CRANES

The crane is a fantastic piece of equipment. It saves us an enormous amount of work. But like anything else that’s big and powerful, it can be dangerous. That’s why I’ve taken the time to stress that you be extra careful when working around cranes

Week 4- Job Made Ladders

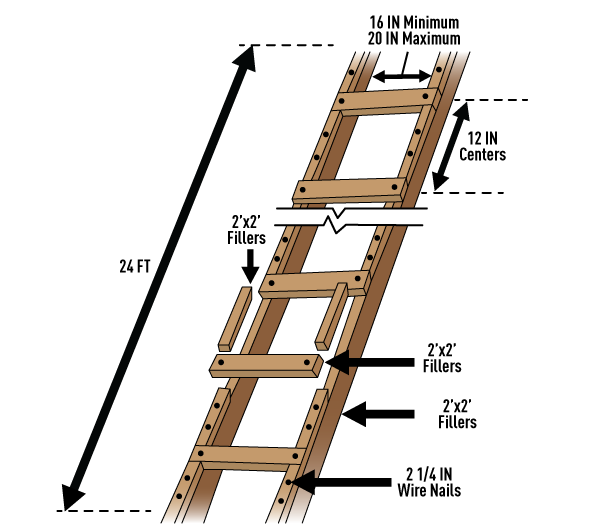

What is a Job-made Wooden Ladder? A job-made wooden ladder is a ladder constructed at the construction site. It is not commerciallymanufactured. A job-made wooden ladder provides access to and from a work area. It is not intended to serve as a work platform. These ladders are temporary, and are used only until a particular phase of work is completed or until permanent stairways or fixed ladders are installed.

If you see job made ladders and they don’t add up to what you see above DON’T USE THEM AND CALL YOUR SUPERVISOR/REGIONAL SAFETY MANAGER IMMEDIALY!!

Some examples we see are ladders being built with pallets, using the wrong lumber, not secured up top and at the bottom, using on surfaces that are not flat dry or proper conditions.

Remember it’s you who can prevent injuries to your selves and others!!