WEEK 1

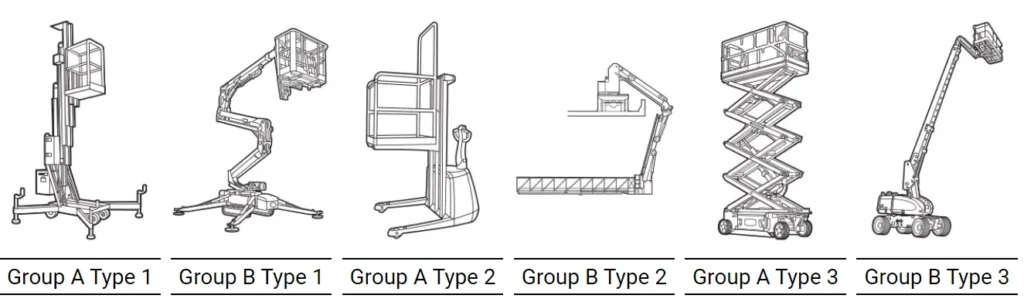

Mobile Elevated Work Platforms (MEWP)

TOOLBOX TALKS TOPIC: MOBILE ELEVATED WORK PLATFORM (MEWP) OPERATOR

The American National Standards Institute (ANSI) requires the employer (VSC) to ensure that employees who operate, occupy and supervise MEWP’s are trained, qualified and authorized in the intended use, safe operation, inspection, maintenance and familiarization on different models and classifications of MEWPs. To ensure compliance with these new standards and to prevent potential accidents and OSHA citations, VSC Risk Management is publishing this notice of responsibilities for VSC MEWP Operators:

OPERATOR RESPONSIBILITIES:

- Operators must be trained in accordance with ANSI A92 for the type and group of MEWP to be used, and be authorized by VSC using required documentation.

- Know your job tasks and possible hazards associated with the tasks.

- Select a MEWP appropriate for the job tasks. Ensure MEWP is appropriate for scope of work and site conditions.

- Verify the rental company has inspected the MEWP for use, and MEWP has a current annual inspection.

- Perform and document daily pre-use inspections.

- Report any maintenance, repairs or damage to the VSC supervisor immediately.

- Know the function of each control.

- Confirm Guard Rails are secure, Access Gate is closed, or chain is connected.

- Ensure load capacity of equipment is clearly visible and posted on the MEWP.

- Know the manufacturers operator’s manual (MOM) safety rules and confirm it is provided on the MEWP in a weatherproof compartment.

- Do not make any modifications without authorization.

- ENSURE OCCUPANTS have basic knowledge to work safely…

- Use of fall protection 100% of the time on any lift.

- How their actions can affect Stability of equipment

- Use of accessories

- Work procedures related to operation of lift.

- Hazards related to tasks

- Purpose and function of controls

- MOM’s (Manual) warnings and instructions (Do not operate if there is no manual)

- Instruct a person who is on site to operate the lower auxiliary controls in case of emergency.

- Ensure a fall rescue plan is in place.

- Perform hazard assessment of work site conditions and job tasks involving use of MEWP.

- Know the hazards associated with the use of MEWP and the means to protect against hazards

WEEK 2

TOOLBOX TALKS TOPIC: Confined Spaces

Are Inspection and Service technicians entering Confined Spaces?

What are some examples of confined space? Black flow pits, tanks, manholes, silos, sometimes trench’s depending on entering/exiting, etc.

For any confined space entry the person entering must be trained and the person the attendant at the top should be trained. Should have a permit process in place and the right type of tripod system for retrieval in case of emergency. The air should be monitored in the space continuously for 15 minutes before entering and throughout the process while in the pit to make sure there are no harmful gases.

To prevent injury, citations and help Inspectors & Service technicians identify whether the space they are about to enter classifies as Confined Space read bullets below. If you are reading this and realize you need training contact your supervisor or local Safety Manager.

As classified by OSHA a Confined Space is a space that meets two or more of these requirements:

- 4 Ft or deeper

- Potential of atmospheric hazards.

- Not designed for continuous occupancy

- Limited means of egress. (Obstructions or configuration of space restricts your ability to quickly escape)

- Engulfment hazards

WEEK 3

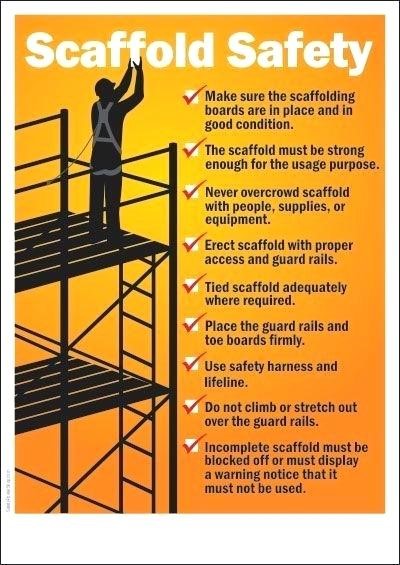

Scaffolding

WEEK 4

Leadership Safety

What is Safety Leadership?

A safety leader is somebody who not only exhibits personal safety behaviors but inspires others to do the same. These are people who not only follow safety protocols to the letter but speak up in a constructive way when they see that others could be doing something in a safer manner.

Who can be a safety leader? Anybody who demonstrates these behaviors:

- Understanding and following safety procedures

- Reporting safety issues when they arise

- Proactively preventing safety issues

- Implementing new processes to improve safety Encouraging others to take safety seriously

Safety leaders don’t necessarily have to be managers or supervisors. It can be anybody who has positive social influence over their peers and an interest in improving safety across the organization. It’s important to note that a safety leader should be less like a hall monitor and more like a cultural influencer. The best safety leaders are the people who help their peers improve without them even realizing it’s happening. They are the people on the team who others come to for advice about best practices because they know they’ll get a response that is both correct and useful.

I HAVE READ AND UNDERSTAND THE TOOLBOX TALKS FOR THIS MONTH AND CONFIRM THAT

“SAFETY IS PRIORITY NUMBER 1!”