Week 1 Hole Covers on jobsites

It has to be a terrible feeling. One moment your feet are on what seems to be a solid surface, the next moment they’re in mid-air as you begin a fall to a level far below. That’s how a floor opening fall typically happens. A worker at a construction site falls through an opening to a surface below or into industrial machinery on a lower level. Openings in floors and roofs are often part of the work environment during construction, renovation, and demolition. They must be guarded and securely covered so no one can accidentally step in.

Hole covers must be capable of supporting, without failure, at least twice the weight of employees, equipment, and materials that may be imposed on the cover at any one time

Securing and Labeling

- All covers must be secured when installed to prevent accidental displacement by wind, equipment, or employees

- All temporary covers must be marked with the word “hole” or “cover” to provide warning of the hazard

Barriers

- Barriers must be of such construction and mounting that, when in place at the opening, the barrier can withstand a load of at least two hundred pounds applied in any direction (except upward), with a minimum of deflection at any point on the top rail or corresponding member

- Screens must be of such construction and mounting that they are capable of withstanding a load of at least two hundred pounds applied horizontally at any point on the near side of the screen

- They may be of solid construction of either grill work with openings not more than eight inches long, or of slat work with openings not more than four inches wide with length unrestricted

Remember we can be cited for working around exposed holes or fall hazards. It is important that when we are working around these areas or we leave for any reason the hole must be covered and protected.

Week 2 Guardrails

One of the more common OSHA citations is for lack of or improperly erected guardrails. There are two basic types of guardrail, the perimeter guardrail (i.e., found on flat roofs, upper stories before framing walls) and floor opening guardrails. Both are constructed the same way and are designed to provide the same type of protection. All open-sided floors or floor openings exposing workers to a fall of six feet in construction to a lower level must be protected

Standard Specifications

- The top rail should be 42? high and constructed of 2×4 stock wood.

- The intermediate (or mid rail) should be 21 (also using 2×4).

- The bottom rail or toe board should be at least 4? in vertical height from the floor to the top of the toe board.

- Uprights will be 2×4 at 8” centers at a minimum.

- All components must withstand a load test of 200 pounds at any point.

General Rules

- Install guardrails properly the first time and reduce the amount of maintenance.

- Regularly inspect all rails in your working area to ensure no maintenance is needed

- Window and Door Openings must have fall protection as well

- Interior stairwells requiring handrails around all areas of exposure

- Anyone repairing a guardrail at elevated heights should be wearing their Personal Fall Arrest System (PFAS) and be tied off to an anchor point.

- Enforce replacement by subcontractors when they remove them.

Remember: Guardrails are designed to protect you from falling from one level to another. If the guardrail is defective or not there at all, then you are exposed to serious injury or even death

Week 3 Asbestos Dangers

Asbestos is a material that was widely used in many building materials which are still found around us today. While it is still in use in a few different materials today, much of its use was stopped in the late 1980s after research revealed the negative health effects associated with its fibers. Many people have heard that asbestos is bad for human health, but do not understand how or why this is the case.

How is Asbestos Bad for Our Health?

Is “carcinogenic to humans.” A carcinogen is defined as any substance or agent that tends to produce a cancer. The reason this mineral is a carcinogen is because of the effects its fibers have on human lungs. Asbestos is made up of extremely small fibers that are naked to the human eye. These fibers can become airborne and stay suspended in the air. When they are breathed in, the fibers can make it past our bodies’ natural defenses and get lodged into the tissue of our lungs. When this occurs, scar tissue begins to form, which reduces the function of our lungs. It eventually progresses to disability and death. Mesothelioma is a common deadly illness caused by exposure to these fibers. Sometimes the effects are not realized for decades after the exposure.

Ways to protect yourself

- Stop work immediately and contact Safety and Supervisor if you believe you are working on or around Asbestos

- The customer or General Contractor must provide VSC with an abatement letter before work can begin.

- Ensure you are not cutting, breaking, or providing air exposure any material that has asbestos containing material.

Remember Asbestos and Silica are the same in the sense as long as we don’t expose the material we stay within the limits.

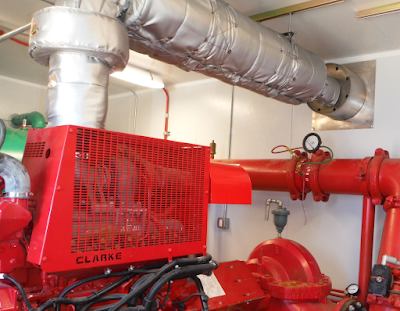

Week 4 Diesel Exhaust

On construction sites, mines, and other types of work sites, diesel engines are used frequently. Diesel engines power everything from water pumps to heavy equipment that allows for day-to-day activities to be completed efficiently. While these engines are great tools, precautions need to be taken to protect workers from being over-exposed to diesel exhaust. Workers exposed to diesel exhaust face the risk of health effects ranging from irritation of the eyes and nose, headaches, and nausea, to respiratory disease and lung cancer.

Diesel exhaust is a mixture of gases and particulates produced during the combustion of diesel fuel. The very small particles are known as diesel particulate matter (DPM), which consists primarily of solid elemental carbon (EC) cores with organic carbon (OC) compounds adhered to the surfaces. The organic carbon found in the exhaust includes a hydrocarbon that has been shown to cause cancer in test animals

Safeguards to Protect Workers

- Limit workers’ time spent in an area with higher levels of diesel exhaust. Diesel exhaust safety

- Properly ventilate any areas where there may be high levels of exhaust.

- Perform routine air monitoring to ensure levels are not at a dangerous level.

- Perform routine preventive maintenance of diesel engines to minimize emissions.

- Install engine exhaust filters.

- Install cleaner-burning engines.

- Using special fuels or fuel additives (e.g., biodiesel).

- Provide equipment cabs with filtered air.

- Install or upgrade main or auxiliary ventilation systems, such as tailpipe or stack exhaust vents to capture and remove emissions in maintenance shops or other indoor locations.

- Prohibit unnecessary idling or lugging of engines.

- Restrict the amount of diesel-powered equipment in an area.

- Designate areas that are off-limits for diesel engine operation and/or personnel travel.