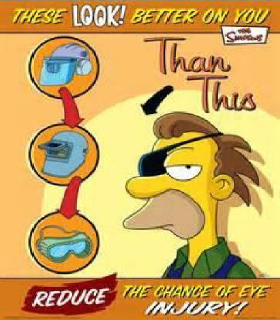

HAZARD:

In the past five years, 22 VSC employees have suffered eye injuries requiring medical treatment from a doctor. The expense related to this medical treatment has been in excess of $10,000. This does not include the cost of lost time or the negative impact on VSC’s OSHA recordable injury rate. In almost every case the injured employee contributed to the injury by not wearing the required eye protection, namely Safety Glasses or Safety Goggles! Typically the job tasks involved drilling or working overhead where the employee was struck by falling and flying debris, encountered airborne dust and particles at construction projects, when removing ceiling tiles during alarm and sprinkler inspections, and being splashed by liquids or chemical exposure during inspections and testing of systems.

PREVENTATIVE MEASURES:

VSC’s Personal Protection Equipment (PPE) Safety Policy explains in detail the mandatory eye protection requirements. The following is a summary of these requirements:

Sprinkler Fitters:

- Safety Glasses must be worn at all times.

- Goggles or face shields are mandatory when drilling, cutting or grinding or job tasks that involve overhead workwith the potential for falling debris. Goggles are to be worn when working with anti-freeze systems due to thepotential for splash or discharge of these chemicals.

Inspections, Testing and Alarms Service Technicians:

- Safety glasses must be worn when conducting tasks or operating equipment that have the potential for eyeinjury. Be especially mindful of tasks that involve working overhead where debris has a tendency to falldownward, or where there is the potential for objects to project or fly forward toward the eyes.

- Goggles or face shields are mandatory when drilling, cutting, grinding, or working around splash hazards and jobtasks that involve overhead work with the potential for falling debris.

Fire Extinguisher/Range Hood Technicians:

- Safety Glasses must be worn when conducting tasks or operating equipment that have the potential for eye injury.

- When charging suppression systems, a face shield will be worn in addition to Safety Glasses.

- Due to the splash hazard associated with refilling Kitchen Suppression Cylinder’s, goggles must be worn.

Shop and Warehouse Employees:

- Safety Glasses must be worn when conducting tasks or operating equipment that have the potential for eye injury.

- When performing hot work, eye protection and/or shields must be worn that are specifically designed to protect against the generated hazard(s).

- Goggles with face shield are required when cutting, grinding, drilling or working around splash hazards.

Fabrication Shop Employees:

- Safety Glasses must be worn at all times. Goggles or face shields are mandatory when drilling, cutting or grinding.

- When performing hot work, eye protection and/or shields must be worn that is specifically designed to protect against the generated hazard(s). For additional information, refer to PPE requirements outlined in Appendix N. “Welding, Cutting, Hot Work Safety Program” of the VSC Health & Safety Program.