Hazard:

Safety Audits conducted by VSC’s Field Safety Managers identify fall protection harnesses and lanyards in unsafe condition due to wear, improper storage, and exposure to chemicals & sharp objects. Fall protection equipment is a life saving device that is to be maintained in a separate location or container away from potentially damaging items such as the blade of a band saw, drill bits, chemicals, direct sunlight or hot work nor tossed on the floor, where it can be damaged by equipment. Damaged and worn PFAS can malfunction during a fall resulting in fatal or serious injury. PFAS are also at risk of failure if it does not meet the test requirements established by American National Standards Institute (ANSI Z359). These violations and hazards are easily preventable when the equipment is properly inspected prior to each use by the user, as per OSHA’s guidelines.

PFAS must be inspected prior to use for mildew, wear, damage, defective components, and other deterioration that may limit its ability to protect the user. PFAS must be removed from service if their strength or function may be adversely affected and replaced when the manufacturers date printed on the ANSI labeling is greater than five years from the calendar date of your inspection. As stated in the standard, personal fall arrest systems must be regularly inspected for the following:

Webbing

Grasp the webbing with your hands and bend the webbing, checking both sides. Webbing damage may not show up during a sight (visual) inspection only – manually manipulating (touching) the harness is equally important.

Look for:

- Cuts, nicks or tears

- Overall deterioration

- Fraying/Abrasions

- Hard or shiny spots (indicates heat damage)

- Mildew (clean the harness)

- Undue Stretching

- Material marked w/permanent marker or sharpie

- Broken fibers/cracks

- Modifications by user

- Discoloration of material

- Webbing thickness uneven (indicates possible fall)

- Missing Straps

- Burnt, charred or melted fibers

- Excessive hardness or brittleness

Stitching

- Pulled stitches

- Stitching that is missing

- Hard or shiny spots (indicates heat damage)

- Cut stitches

- Discoloration of stitching

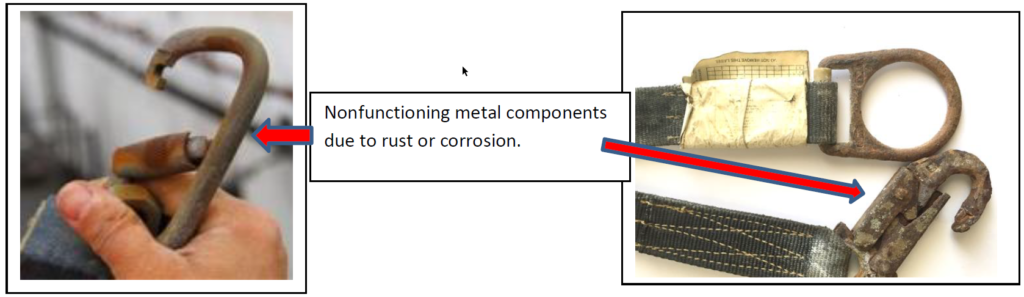

Hardware

- Distortion (twists, bends)

- Rust, Corrosion, Cracks or Breaks grommets

- Modification by users (i.e. additional holes)

- Bent/damaged Bars (they must be straight)

- Rough or sharp edges

- Broken/distorted grommets

- Roller of tongue buckle should turn freely on frame

- All springs must be in working condition

Any component showing any of these signs of damage should be withdrawn from service immediately by tagging or marking the PFAS “DO NOT USE”, by destroying the PFAS, and giving the out of service PFA to your Supervisor for disposal.

ANSI test data tag must be legible as seen here