Hazard:

Falls remain the number one cause of fatalities in our industry. The number one root cause is human error.

A common challenge is locating an anchor point “tie off” to attach the harness lanyard. Attaching the

lanyard to an anchorage that will not meet load requirements or failure to use the lanyard can result in

injury or death!

Examples of none-approved anchors:

- Standard Guardrails

- Standard Railings

- Ladders/Rungs

- Scaffolding

- Light Fixtures

- Conduit or Plumbing

- Ductwork or Pipe Vents

- C-Clamps

- Wiring Harnesses

- Rebar (except for positioning during formwork)

- Another lanyard

- Roof Stacks, Vents or Fans

Preventative Measures:

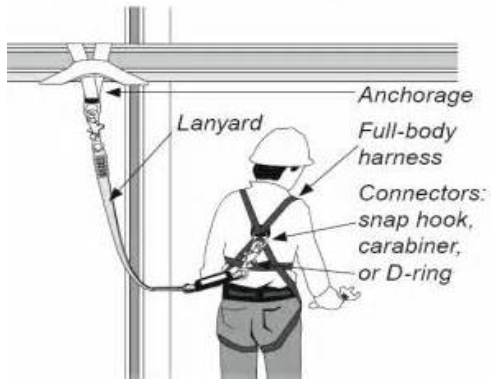

The full body harness with shock absorbing lanyard that VSC provides for all employees, also known as Personal Fall Protection, is designed to a limited force of 900 lbs. and when engaged must be anchored / attached to a point that will support 1800lbs. (also known as a safety factor of two)

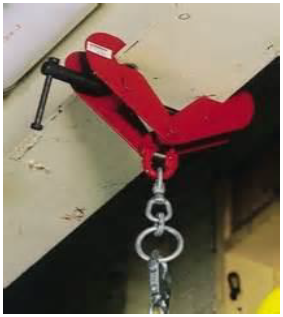

The anchorage points for shock absorbing lanyards are determined by the structural integrity of the material to which you are tying off. Steel vertical or horizontal I beams, metal roof trusses, & reinforced rebar frame work is the preferred choice. However, when these are not an option cross sections of wood trusses in ceiling or an approved concrete insert connection device would be appropriate.

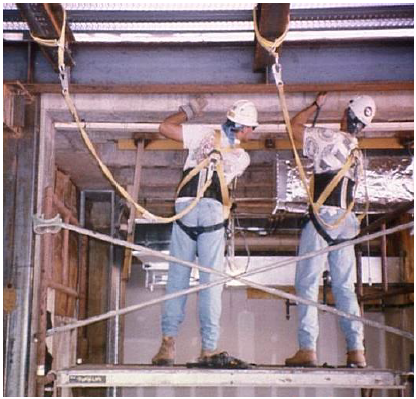

Examples of Good Anchorage Points:

Anchor points are also chosen from an overhead

connections point at the highest position above the

employee to minimize the fall distance!