Week 1 Toolbox Talk- Material Handling and Lifting in Special Situations

Most people whose jobs require lifting are familiar with the “safe” lift — bending your knees, hugging the load, and letting the strong muscles in your legs do the actual lifting. This standard way of lifting is safe, but in many situations, it’s impractical. When the load you have to lift is awkward or is in a hard-to-reach area, a standard lift can be difficult to perform. The following tips can help you lift safely in situations where the standard lift can’t be used.

Odd-sized loads – Long objects that are relatively light can be awkward to lift and carry. When lifting and carrying pipes, conduit, or other long, light loads, don’t “hug” the load close to your body. Instead, support it on your shoulder, keeping the front end of the object higher than the rear.

If the load is long or heavy enough to require two people, each of you should shoulder it on the same side and keep the object level. Be sure to keep in step when walking. Some over-sized loads may be light enough to carry but can block your vision. In those situations, it’s best to use mechanical help or ask a coworker for a hand.

Hard-to-reach loads – Overhead loads can be difficult to lift. If you have to lift an object that’s above shoulder level, use a stepstool, ladder, or lift to avoid over-reaching. Test the weight of the load before removing it from its shelf. If it’s under 25 pounds or so, slide it toward you and hug it close to your body as you step down the ladder. If possible, hand it down to a waiting coworker.

Reaching down into a bin, container, or other storage area to lift an object makes the standard lift next to impossible. In these situations, stand with feet at shoulder distance apart, slightly bend your knees, and start to squat, bending at your hip joints rather than your waist – just as you would do when you lower yourself into a chair. Slide to load as close to your body as you can and raise yourself using your leg and hip muscles. Tighten your abdominal muscles as you lift, and if possible, rest your knees against the side of the container for additional support.

Tips to remember – Whenever possible, use the standard lift. But, if a load is awkward, use these tips to help you lift safely. Avoid extending your upper body to lift a load — you’ll not only lose your center of balance, you’ll also risk injuring your back. Finally, use your safety sense — if a load is too awkward or is hard-to-reach — get help!

Week 2 Toolbox Talk-Tornado Safety

Tornado Safety at Work and Home

The first thing to know when it comes to tornadoes is the difference between a tornado watch and a tornado warning. A watch is when tornadoes are possible in and near the watch area. A warning is when a tornado has been sighted or indicated by weather radar. A warning indicates there is a tornado that is an imminent danger to life and property in that area.

Have a plan for when a tornado threat is in your area. Pick a room in your home where it is safe to go during a tornado. Areas such as basements or an interior room on the lowest floor are the best places to take shelter during a tornado.

At work, know how you will be notified by the company that tornado conditions could be in the area. Know where the tornado shelter is onsite or if the company uses one in the community. Some companies that do not have a tornado shelter onsite will send everyone home as soon as there is a tornado watch in effect. Knowing what to do and executing the emergency plan is essential to protect yourself and those around you.

Make sure you know and understand the emergency action plan at the office or on the jobsite, a copy of VSC is located on the safety webpage.

Week 3 Toolbox Talk- Situational Awareness

What is situational awareness?

Situational awareness refers to being aware of what is happening around you, where you are in relation to other people and things, and what potential threats may be present. Situational awareness is a critical foundation for successful decision making at work. Many of these situations can involve your health, your safety, and your job performance. Many accidents related to errors or mistakes can be attributed to a lack of situational awareness.

How To Improve Situational Awareness

Assess risks from all angles- You should learn to look at things with a 360-degree focus, not just from your view. Can you see what others are seeing? How is it different from what you see? Are there other factors that can impact the situation? Question everything! Questioning without judgment is a key factor in successful situational awareness.

Consider the subconscious- For you to effectively engage in situational awareness, make logical decisions, and look to the future with a strategic focus, the subconscious must be engaged and assessed. Simply put, in order to have situational awareness you have to be open to a variety of perspectives and insights. This is how your strengths and opportunities for improvement can be identified. If you are biased in your views, it can lead to risks for you and your coworkers.

Communicate with others- Your ability to communicate your perception of risks with others is a vital part of awareness strategy. An effective strategy requires that everyone be on board, and the best way to achieve that is to be able to communicate with each other. You should be able to communicate the potential hazards at each stage of a risk assessment with everyone that is involved. In other words, instruct workers on the safest way to do things or tell your supervisor about health and safety hazards you see on a jobsite. It can also mean that you ask for help when you know that you need it, like if a job is too risky for one person to do it, or if a machine seems faulty.

Work as a team- It is important to practice situational awareness if you have a management role or even the role of a team leader. If your team sees you doing it, then they are likely to follow. If team members see each other doing it, then they will all follow suit eventually. Everyone should make a conscious effort to have a 360-degree view of situations and show others the importance of doing so.

Week 4 Toolbox Talk- Heat Related Illness

We are starting to get into a time when the weather is getting warmer and if we are not ready, we can run the risk of receiving a heat-related illness. These are on the rise and can affect anyone wither they are working outdoors or indoors.

Knowing the signs and symptoms is the first way to prevent yourself from getting sick or even killed.

Heat cramps- Heat cramps are debilitating painful muscle cramps that are caused by working in a hot environment. They may start while you are working or up to a couple of hours after you leave that environment. The muscles affect are typically the ones being used the most, like calves, hamstrings, hands, or lower back.

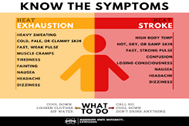

Heat exhaustion- Heat exhaustion is the body’s response to an excessive loss of water, salt, and both. Left untreated, heat exhaustion can lead to heat stroke.

Symptoms of water depletion (or dehydration) include:

- Excessive thirst

- Headache

- Weaknesses

- Loss of consciousness

- Nausea

- Vomiting

- Muscle Cramps

- Dizziness

Heat stroke is the ultimate breakdown of the body’s temperature control system. It occurs when the body can no longer control its temperature, resulting in a rapid rise in body temperature that can cause organ damage, brain damage, and even death. Heat stroke is the most serious type of heat illness on the construction site because it is life-threatening. In non-lethal cases, heatstroke can still result in permanent disability, so it’s imperative that those suffering heat stroke symptoms receive emergency treatment.

Symptoms of heat stroke include:

- Fainting, High Body temp, Powerful headache, Lack of sweating, Vomiting and Confusion