HAZARD:

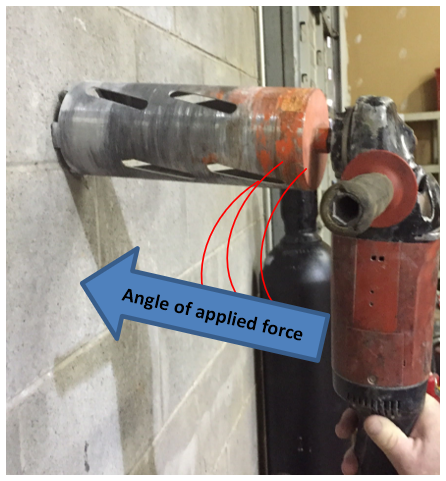

The use of grinders for core drilling can cause serious injury! The 90 degree angle of the grinder does not allow the operator to apply direct even force perpendicular to the wall. As the grinder is being pushed forward at an angle towards the wall it causes the tool to tilt and the teeth of the saw to bite on one side. This wears down the saw creating increased physical strain on the operator as he tries to maintain control. The grinder will bind and jerk counterclockwise causing injury to the operator’s hands & wrists. When working from a ladder the quick, violent force from this binding and jerking reaction can cause the operator to fall from the ladder, possibly being struck by the tool as he falls.

Hole Saws are not approved by tool manufactures as a grinder attachment. The grinder RPM exceeds the RPM of the saw and the tool is not designed with a gear clutch mechanism to prevent the tool from binding when cutting into rebar or other obstructions imbedded in concrete. These combined hazards lead to an increase risk of injury to shoulders, back, hands & wrists. When working from ladders, the violent reaction from binding/cutting will throw the employee from the ladder with the tool striking the employee.

When injuries occur, OSHA will cite VSC for unauthorized use of the tool. The Result: The employee suffers an injury and VSC suffers the financial penalty! No one wins because “We’ve always done it that way”! Also note: Because of the increased risk of injury, manufacturers of grinders strongly discourage use of the tool in the manner described above. In addition, this misuse voids the manufacturer’s warranty on the tool!

| Please Note: Core drilling is a “skilled trade task”. Per OSHA, it should only be performed by trained, experienced personnel. VSC Risk Management conducting site safety audits have discovered inexperienced untrained employees, often a “helper”, performing core drilling. In most cases they do not know the hazards or preventative measures and often do not wear appropriate PPE! These factors combined with not using the proper tool greatly increase the likelihood of serious injury! |

Preventative Measures

A Core drill tool (as seen here) is designed to apply direct force behind the saw during operation, allowing all teeth of the saw to cut flush to the surface of the wall simultaneously, requiring less physical exertion by the operator! The tool and saw match RPM’s, and the tool is designed with anti-seize clutch to prevent binding when in contact with embedded obstructions. These safety features also reduce the amount of physical exertion and force by the operator.

“Limited space” is a common excuse operators have for using a grinder.

Remember: There are smaller drills to use for tighter restricted areas without the use of an anchored base plate!

Note: Hole saw attachments are only for concrete block & brick walls. For solid concrete wall and flooring, optional percussion core bits must be used as seen here…